Custom Facility Lighting System Packages

Let us Design, Specify Or Quote any size Lighting Project For You.

Contact Us Toll Free 1-866-654-3961

Click Here For Fracking Facility Lighting Gardendale, Texas - PHOTOMETRIC

Background Background

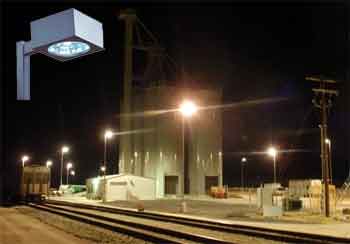

The Garden Dale Facility is a new construction, fracking sand depot in Catulla, TX. It is owned and operated by Halliburton. H2 Engineering is the general contractor responsible for building the facility. RLLD Commercial Lighting was subcontracted by H2 Engineering to design and install a turnkey Fracking Sand Depot Facility Lighting System for the grounds.

The facility itself is located at the end of a mile and a half of roadway. It consists of 110,000 square feet of paved work area. Within the work area, stand several 80-100 foot silos that hold sand used in fracking (a process that extracts natural gas). Several buildings and a paved parking lot are also located at the site, and a small crew runs the operation.

The sand is brought in on rail cars that load it into the silos. The roadway that runs through the depot loops back on itself, allowing trucks to line up single file, enter the facility, load the sand into trailers, and then exit in the direction they entered. The sand is brought in on rail cars that load it into the silos. The roadway that runs through the depot loops back on itself, allowing trucks to line up single file, enter the facility, load the sand into trailers, and then exit in the direction they entered.

Challenge

A fracking sand depot facility lighting system had already been developed. However, the system was designed with equipment that was way over budget. Costly LED lights had been planned for the roadway lighting system, and there were twice as many industrial area lighting poles as were needed. Also, the foot candle average in the work area was determined to be twice as high as necessary.

H2 Engineering requested that we design them a more cost effective fracking sand depot facility lighting system within the following parameters:

· Foot candle average along the roadway should be 1/10 lumens per foot.

· Foot candle average in the work area should be 5 lumens per foot.

· Reduce the number of industrial area lighting poles by incorporating a more efficient light distribution pattern into the design.

We would also need to relocate three industrial area lighting poles that had been specified in the original proposal. These proposed locations were far too close to the railroad tracks. They would have to be moved to the interior without compromising the level of light.

Equipment at a Glance

Our fracking sand depot facility lighting system consisted of pulse start metal halide fixtures for roadway lighting and industrial area lighting. Full cutoff fixtures were mounted on thirty-eight poles measuring 35 feet in height were mounted on concrete bases that stand 3 feet off the ground. 400W fixtures were chosen for the roadway, and 1000W fixtures were used to light the parking lot and the paved work area.

These fixtures use vertical lamps that are made in the USA . They are protected from wind, sand, and high heat by a powder coated finish.

Solution

The pulse start metal halide lamps in our fracking sand depot facility lighting system are energy efficient. This gives them a longer lamp life than standard metal halide and high pressure sodium lights and minimizes repair and replacement costs.

Foot candle average along the roadway was redesigned to the industry standard 1/10 lumen per foot. The 400W fixtures we used were sufficiently energy efficient for this task, and they were far more cost effective than the originally proposed, LED lights.

As previously noted, the originally proposed fracking sand depot facility lighting system had called for an excessive10 lumens per foot.

By reducing this to 5 lumens per foot, we were able to produce a high level of light with clear visibility using only half as many 1000W fixtures.

Fixture reflector type was highly instrumental to keeping our fracking sand depot facility lighting system within budget. Poles were placed in accordance with the pattern of light output emitted by each fixture.

· Poles along the roadway were fitted with type 3 reflectors that yield an excellent throw on both sides of fixtures. This produces an elongated lighting pattern conducive to roadway lighting.

· Poles used around the perimeter of the work area were fitted with type 4 reflectors that yield a forward throw that avoids wasting light behind the pole

· The three industrial area lights that were moved to the interior were fitted with type 5 reflectors. These reflectors emit light in a circular pattern in all directions.

Results

The cost of our industrial area lighting system fell within acceptable parameters of the budget. We have since implemented a turnkey solution that involves the following services:

· The digging of 6,000 feet of underground trenching, along with the design and installation of the electrical system

· The design and installation of the electrical system

· Construction of concrete pole bases and installation of poles

· Installation and testing of light fixtures

RLLD Commercial Lighting carries a wide variety of commercial & industrial lighting fixtures including sport lights, parking lot lighting and gooseneck lighting fixtures. If you can not find what you are looking for call us toll free at 1-866-654-3961 and we will find it for you. Our home office is located in Houston, Texas with warehouses located throughout the United States that enable us to service all 50 states. |